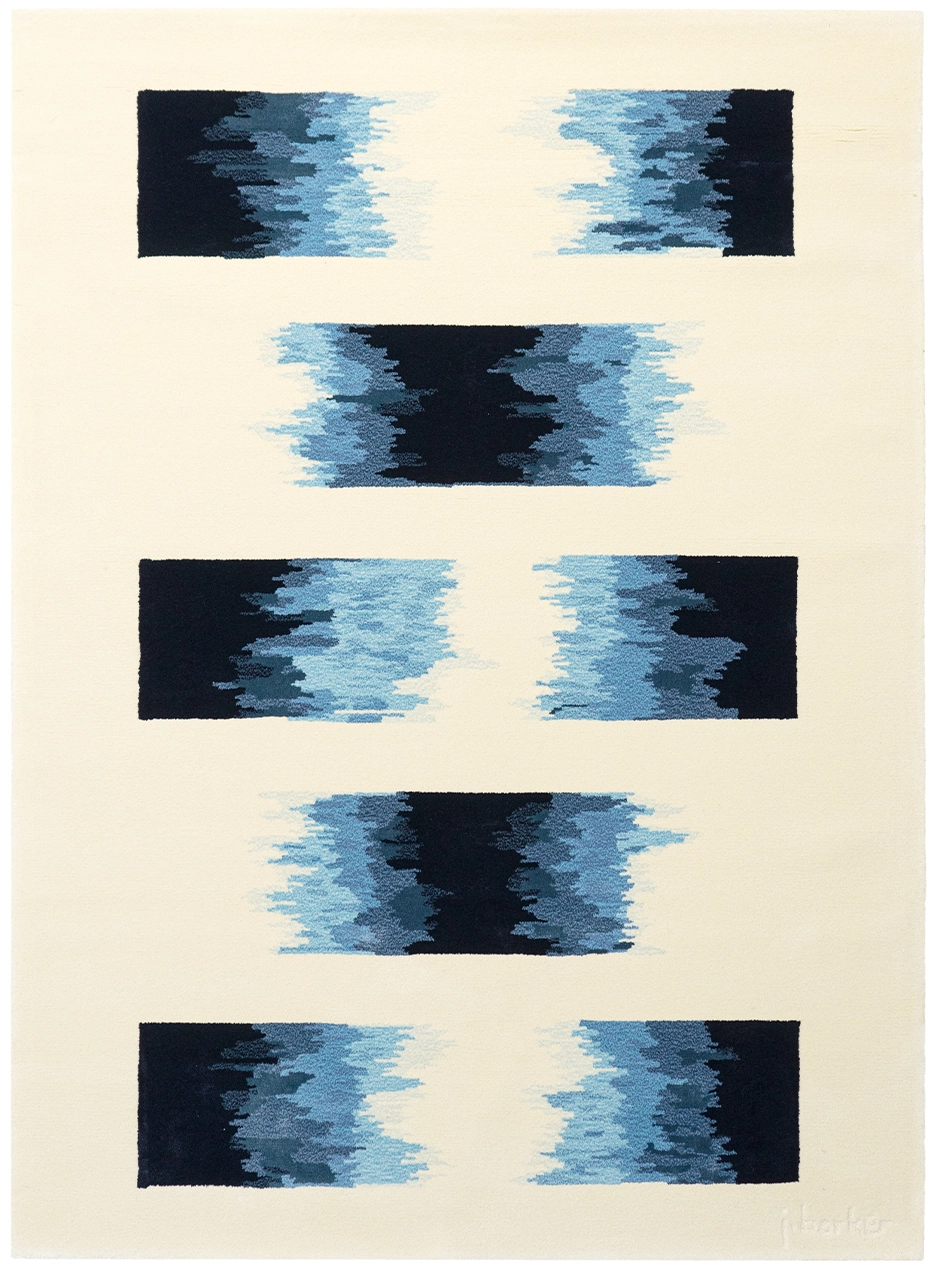

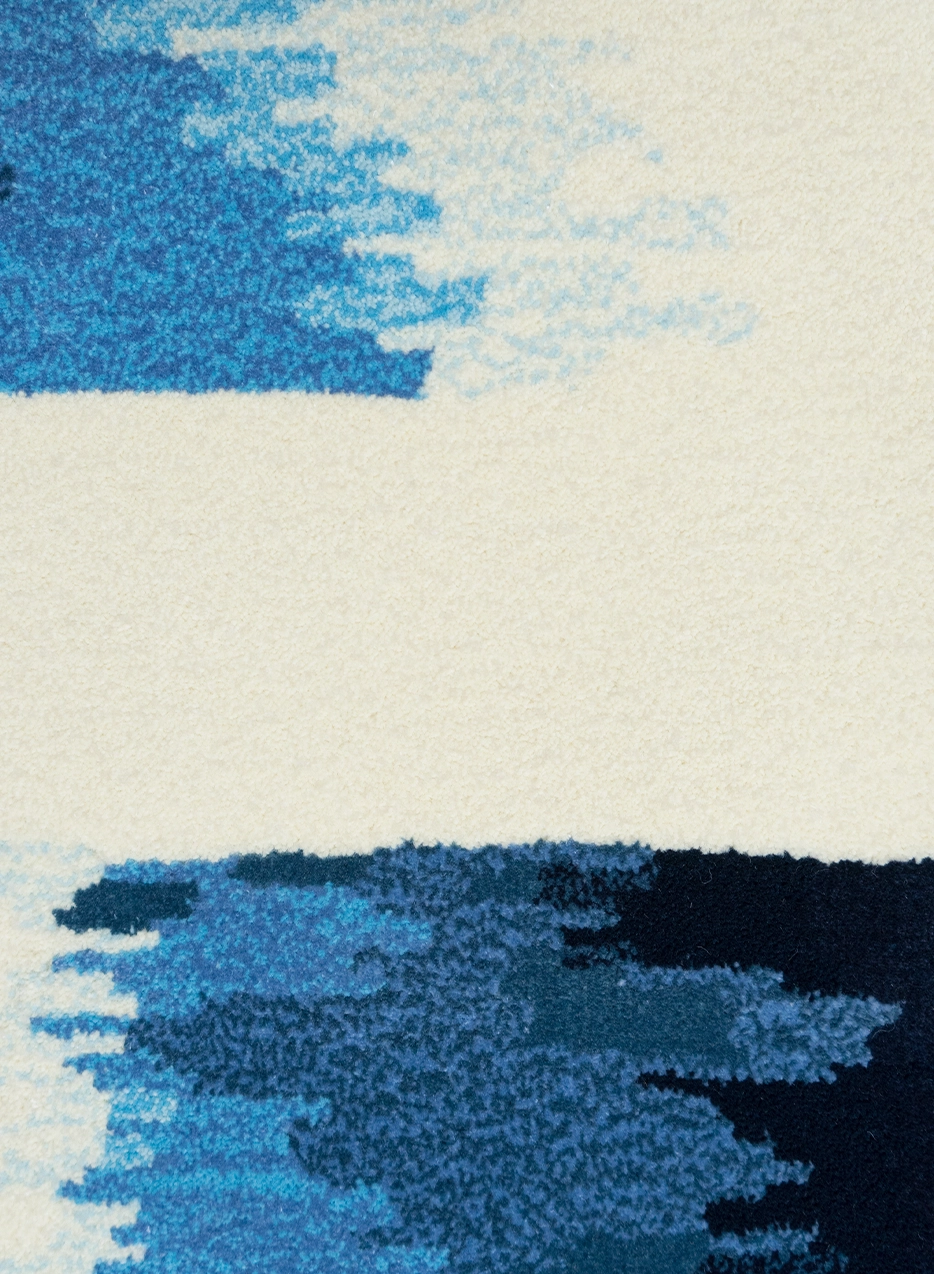

Kindy

by Jacques Borker

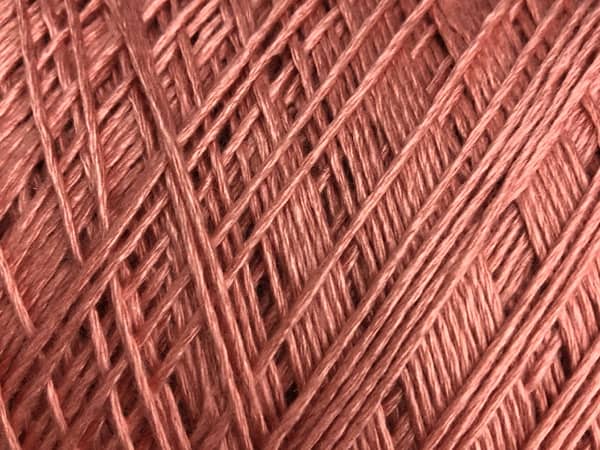

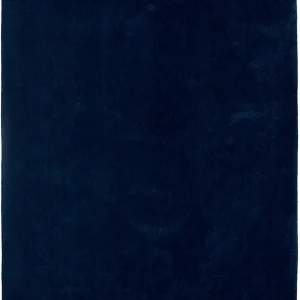

MATERIALS Wool & Tencel

TECHNIQUE Hand tufted

SIZE 250 x 180 cm

PRICE ON REQUEST. CONTACT US.* Price incl. VAT includes : Packaging of the product and home delivery regardless of your country of residence.

Out of stock

Description

tencel

Tencel®, which is a registered trademark and another name for lyocell, is produced from wood pulp, usually eucalyptus. It emerged very recently in the textile industry: made for the first time at the end of the 1980s, it was marketed in 1992. Produced in Europe, this material is particularly innovative. Its production process is very quick since it takes only two hours from wood harvesting to spinning. Cultivating the timber necessary to its production is a particularly clean process: it needs very little water and no pesticides. This textile fibre is very soft to the touch, elastic, resistant and durable. It has excellent moisture absorption properties while remaining dry on the surface. Lyocell lends itself perfectly to blending with other materials and gives PINTON rugs a very smooth contemporary twist.

bamboo

Bamboo fibre is a recent newcomer in the textile industry. It is made from bamboo paste: part of the bamboo pulp is dissolved to produce a thick liquid called viscose, which is then filtered and extruded through a plate with tiny holes to form continuous threads. Bamboo has a much higher yield than any other natural fibre. The culture of the bamboo plant requires no chemicals and offers a formidable capacity for carbon storage, while producing large quantities of oxygen. In addition to its environmental credentials, bamboo captures moisture and proves very resistant. Finally, it is exceptionally soft and welcoming. In the PINTON Manufacture and PINTON Edition divisions, bamboo has its place in the composition of the rugs to which it lends its unique properties and shine!

Bamboo can be used in loop weave where the continuous thread forms loops on the surface of the rug, or in pile weave where the threads on the surface of the rug are cut. It can also be woven as loop and cut which combines both techniques.

hand tufted

The hand tufting technique is a process combining centuries-old skills and modern weaving tools. The canvas is perfectly stretched over an upright loom and the craftsperson transfers by hand the future design of the rug with the utmost precision. Threads are inserted manually, one by one, working with a gun on the back of the canvas, following the colours, the drawing and the different tuft heights. PINTON was one of the first manufactories to use the gun tufting technique to produce some of its rugs and carpets and is the only French workshop offering very high quality tufted rugs. With this technique, production times are reduced compared to the knotted stitch weave or point noué. Finally, hand tufting offers a large range of possible depths. Carving is the technique that consists in sculpting the wool and creating textures within the woven rug. Since the early 1990s, PINTON has been specialising in the production of hand tufted rugs for which it also collaborates with famous designers and artists.

Jacques Borker

Jacques Borker, born on 29 September 1922 in Paris, France, was one of the first French designers of art carpets. He is currently a painter on plexiglas. Jacques Borker studied various artistic disciplines at the École des Beaux-Arts, where he was a contemporary and friend of Le Corbusier, Charlotte Perriand, Jean Lurçat, Zao Wou-Ki, Pierre Soulages and Hans Hartung. His work has been exhibited in art galleries and museums in many cities around the world, including Paris (e.g. Galeries Lafayette), Stuttgart (Mercedes-Benz Museum), New York, Marseille, London, Geneva, Lausanne, Hong Kong, Frankfurt, New Delhi and Vilnius.

PINTON had the privilege of discovering his entire body of Jacques Borker’s work during exclusive interviews in the artist’s studio: a place brimming with the very essence of his creations and his unparalleled experience as an artist-plastician.